Mixer

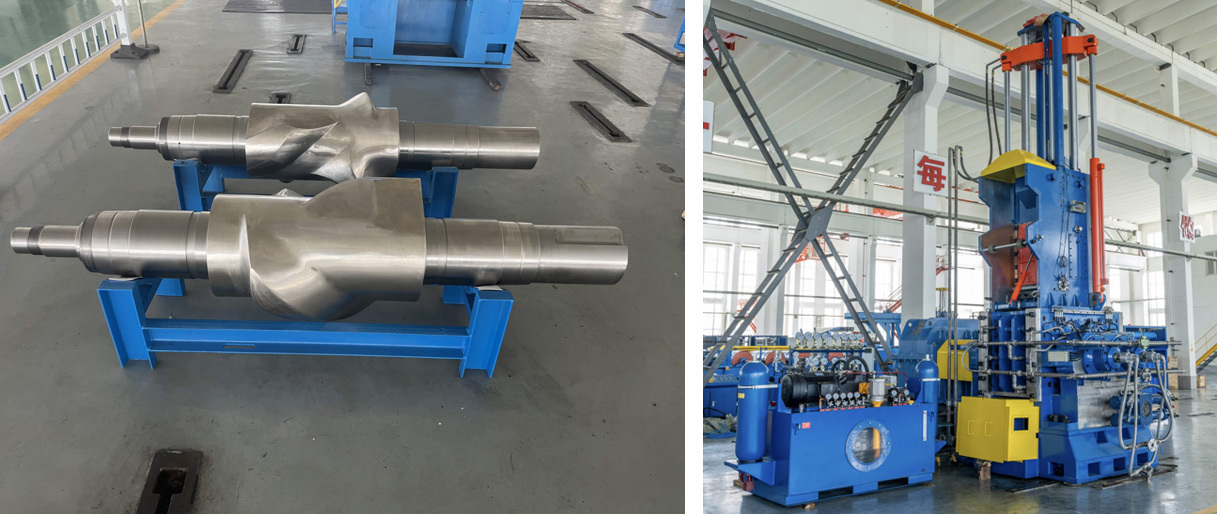

Equipment usage: Used for the plastic and rubber mixing and plasticating.

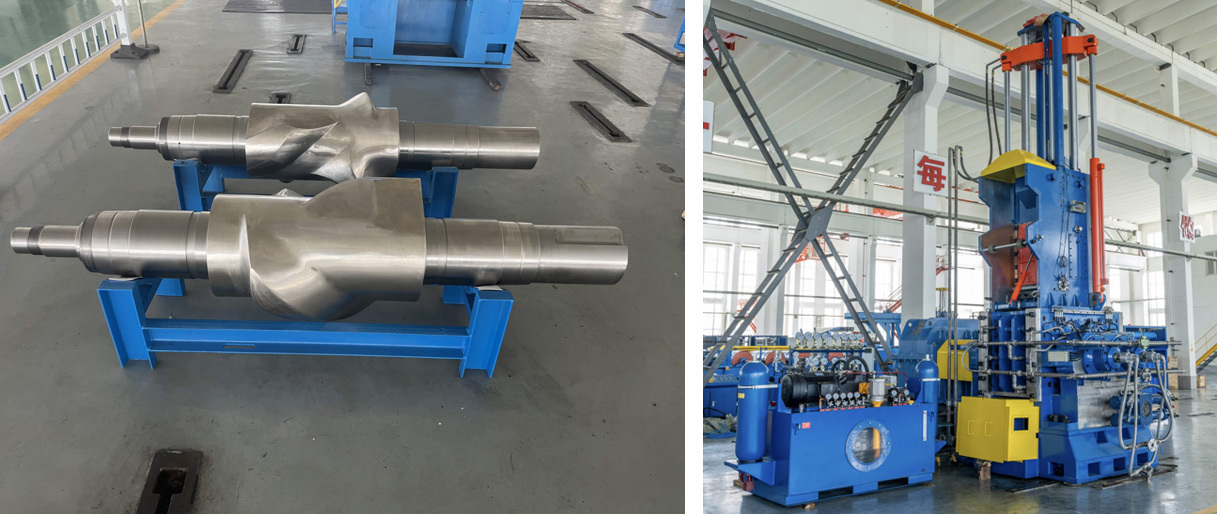

1.The optimized designed tangential rotor and intermeshing rotor can meet the requirements of different designing, formulas, and processes of users.

2. The tangential rotor has two wing, four wing and six wing structure. The intermeshing type rotor has wider wing tip and the meshing area similar to an involute, which can improve the dispersion and cooling effect of the rubber material and improve the quality of rubber mixing.

3. The parts in contact with the rubber material are cooled by water circulation, with a large cooling area. And it can be equipped with the water temperature control system. It can keep the temperature of the rubber mixing at the constant temperature to ensure stable quality of the rubber compound.

4. The control system adopts PLC, which has manual and automatic functions. It is convenient to switch, and can achieve time and temperature control. It also has comprehensive signal detection, feedback, and safety protection, more effectively on the control of rubber mixing quality, shorten auxiliary time, and reduce labor intensity.

5. It is modular design, mainly composed of feeding device, mixing device, locking device, and base. It is suitable for different installation sites and easy for maintenance.

- Summary

- Series Products

- Technical Parameter

- 概要

-

- Commodity name: Mixer

Internal mixer with intermeshing rotor

Item / Model

90E

135E

160E

190E

270E

320E

440E

580E

Total volume(L)

87

140

160

200

250

326

440

563

Volume of Mixing chamber(L)

56.5

91

104

130

162.5

212

286

366

Rotor speed(r/min)

50/60

50/60

40/50

40/60

40/60

50/60

60

60

Speed ratio

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

Motor power(KW)

450/550

630/710

630/800

800/1100

1250/1500

1500/1800

2500

2550

Motor speed(r/min)

1000

1000

1000

1000

1000

1500

1000

1000

Input voltage

AC380V/AC660V/AC10000V

AC660V/AC10000V

Item / Model

90E

135E

160E

190E

270E

320E

440E

580E

ram pressure

Hydraulic ram

0~0.6MPa stepless voltage regulation

Air ram

0.3-0.4

0.3-0.4

0.36-0.48

0.37-0.49

0.37-0.49

0.36-0.48

0.37-0.49

0.37-0.49

Air

Pressure(Mpa)

0.6-0.8

Energy consumption(m³/h)

40

60

70

160

200

300

350

400

cooling water

Pressure(Mpa)

0.2-0.4

Energy consumption(m³/h)

25

40

45

60

80

100

110

130

Overall dimensions

L (mm)

7400

7600

8600

11500

11500

11500

12500

13000

w (mm)

3500

5000

5000

6000

6000

6000

7500

8000

H (mm)

4700

5400

5800

6400

6600

7000

7400

7100

Total weight (T)

25

30

35

44

58

66

93

91

Internal mixer with tangential rotor

Item / Model

50L

80L

110L

160L

250L

270L

330L

370L

430L

Total volume(L)

50

(2Edge)

80(2Edge)

76(4Edge)

110(2Edge)

108(4Edge)

160(2Edge)

147(4Edge)

250(2Edge)

250(SG)

240(TB/SZ)

320(4Edge)

395(SG/TB/6Edge)

425(SG/TB)

Volume of Mixing chamber(L)

37.5

60(2Edge)

57(4Edge)

82.5(2Edge)

81 (4Edge)

120(2Edge)

110(4Edge)140

187.5(SG)

180(TB/SZ)

240

296

319

Rear rotor speed(r/min)

40

40/60

40/60

40/60

20

40/60/70

40/50

40/60

40/60

Rotor speed

1:1.17

1:1.15

1:1.15

1:1.16

1:1.17

1:1/1:1.17

1:1/1:1.16

1:1/1:1.16

Motor power(KW)

110

250/315①

280/400②

280/355①

315/450②

500/750①

630/900②

250(Aerodynamic)280(Hydraulic pressure)

1250/1500/1800

1400/1800

1500/

2500

1500/

2500

Motor speed(r/min)

600

1000

Input voltage

AC380/AC660V/AC10000V

AC660V/AC10000V

①The motor power for 2 wing rotor of 40RPM and 60RPM ;②The motor power for 4 wing rotor of 40 RPM and 60RPM

Item / Model

90E

135E

160E

190E

270E

320E

440E

580E

Ram pressure

Hydraulic ram

0~0.6MPa stepless voltage regulation

Air ram

0.3-0.4

0.3-0.4

0.36-0.48

0.37-0.49

0.37-0.49

0.36-0.48

0.37-0.49

0.37-0.49

Air

Pressure(Mpa)

0.6-0.8

Energy consumption(m³/h)

40

60

70

160

200

300

350

400

Cooling water

Pressure(Mpa)

0.2-0.4

Energy consumption(m³/h)

25

40

45

60

80

100

110

130

Overall dimensions

L (mm)

7400

7600

8600

11500

11500

11500

12500

13000

w (mm)

3500

5000

5000

6000

6000

6000

7500

8000

H (mm)

4700

5400

5800

6400

6600

7000

7400

7100

Total weight(T)

25

30

35

44

58

66

93

91

-

Equipment usage: Used for the plastic and rubber mixing and plasticating.

1.The optimized designed tangential rotor and intermeshing rotor can meet the requirements of different designing, formulas, and processes of users.

2. The tangential rotor has two wing, four wing and six wing structure. The intermeshing type rotor has wider wing tip and the meshing area similar to an involute, which can improve the dispersion and cooling effect of the rubber material and improve the quality of rubber mixing.

3. The parts in contact with the rubber material are cooled by water circulation, with a large cooling area. And it can be equipped with the water temperature control system. It can keep the temperature of the rubber mixing at the constant temperature to ensure stable quality of the rubber compound.

4. The control system adopts PLC, which has manual and automatic functions. It is convenient to switch, and can achieve time and temperature control. It also has comprehensive signal detection, feedback, and safety protection, more effectively on the control of rubber mixing quality, shorten auxiliary time, and reduce labor intensity.

5. It is modular design, mainly composed of feeding device, mixing device, locking device, and base. It is suitable for different installation sites and easy for maintenance.

Internal mixer with intermeshing rotor

|

Item / Model |

90E |

135E |

160E |

190E |

270E |

320E |

440E |

580E |

|

Total volume(L) |

87 |

140 |

160 |

200 |

250 |

326 |

440 |

563 |

|

Volume of Mixing chamber(L) |

56.5 |

91 |

104 |

130 |

162.5 |

212 |

286 |

366 |

|

Rotor speed(r/min) |

50/60 |

50/60 |

40/50 |

40/60 |

40/60 |

50/60 |

60 |

60 |

|

Speed ratio |

1:1 |

1:1 |

1:1 |

1:1 |

1:1 |

1:1 |

1:1 |

1:1 |

|

Motor power(KW) |

450/550 |

630/710 |

630/800 |

800/1100 |

1250/1500 |

1500/1800 |

2500 |

2550 |

|

Motor speed(r/min) |

1000 |

1000 |

1000 |

1000 |

1000 |

1500 |

1000 |

1000 |

|

Input voltage |

AC380V/AC660V/AC10000V |

AC660V/AC10000V |

||||||

|

Item / Model |

90E |

135E |

160E |

190E |

270E |

320E |

440E |

580E |

|

|

ram pressure |

Hydraulic ram |

0~0.6MPa stepless voltage regulation |

|||||||

|

Air ram |

0.3-0.4 |

0.3-0.4 |

0.36-0.48 |

0.37-0.49 |

0.37-0.49 |

0.36-0.48 |

0.37-0.49 |

0.37-0.49 |

|

|

Air |

Pressure(Mpa) |

0.6-0.8 |

|||||||

|

Energy consumption(m³/h) |

40 |

60 |

70 |

160 |

200 |

300 |

350 |

400 |

|

|

cooling water |

Pressure(Mpa) |

0.2-0.4 |

|||||||

|

Energy consumption(m³/h) |

25 |

40 |

45 |

60 |

80 |

100 |

110 |

130 |

|

|

Overall dimensions |

L (mm) |

7400 |

7600 |

8600 |

11500 |

11500 |

11500 |

12500 |

13000 |

|

w (mm) |

3500 |

5000 |

5000 |

6000 |

6000 |

6000 |

7500 |

8000 |

|

|

H (mm) |

4700 |

5400 |

5800 |

6400 |

6600 |

7000 |

7400 |

7100 |

|

|

Total weight (T) |

25 |

30 |

35 |

44 |

58 |

66 |

93 |

91 |

|

Internal mixer with tangential rotor

|

Item / Model |

50L |

80L |

110L |

160L |

250L |

270L |

330L |

370L |

430L |

|

Total volume(L) |

50 (2Edge) |

80(2Edge) 76(4Edge) |

110(2Edge) 108(4Edge) |

160(2Edge) 147(4Edge) |

250(2Edge) |

250(SG) 240(TB/SZ) |

320(4Edge) |

395(SG/TB/6Edge) |

425(SG/TB) |

|

Volume of Mixing chamber(L)

|

37.5 |

60(2Edge) 57(4Edge) |

82.5(2Edge) 81 (4Edge) |

120(2Edge) |

140 |

187.5(SG) 180(TB/SZ) |

240 |

296 |

319 |

|

Rear rotor speed(r/min) |

40 |

40/60 |

40/60 |

40/60 |

20 |

40/60/70 |

40/50 |

40/60 |

40/60 |

|

Rotor speed |

1:1.17 |

1:1.15 |

1:1.15 |

1:1.16 |

1:1.17 |

1:1/1:1.17 |

1:1/1:1.16 |

1:1/1:1.16 |

|

|

Motor power(KW) |

110 |

250/315① 280/400② |

280/355① 315/450② |

500/750① 630/900② |

250(Aerodynamic)280(Hydraulic pressure) |

1250/1500/1800 |

1400/1800 |

1500/ 2500 |

1500/ 2500 |

|

Motor speed(r/min) |

600 |

1000 |

|||||||

|

Input voltage |

AC380/AC660V/AC10000V |

AC660V/AC10000V |

|||||||

①The motor power for 2 wing rotor of 40RPM and 60RPM ;②The motor power for 4 wing rotor of 40 RPM and 60RPM

|

Item / Model |

90E |

135E |

160E |

190E |

270E |

320E |

440E |

580E |

|

|

Ram pressure |

Hydraulic ram |

0~0.6MPa stepless voltage regulation |

|||||||

|

Air ram |

0.3-0.4 |

0.3-0.4 |

0.36-0.48 |

0.37-0.49 |

0.37-0.49 |

0.36-0.48 |

0.37-0.49 |

0.37-0.49 |

|

|

Air |

Pressure(Mpa) |

0.6-0.8 |

|||||||

|

Energy consumption(m³/h) |

40 |

60 |

70 |

160 |

200 |

300 |

350 |

400 |

|

|

Cooling water |

Pressure(Mpa) |

0.2-0.4 |

|||||||

|

Energy consumption(m³/h) |

25 |

40 |

45 |

60 |

80 |

100 |

110 |

130 |

|

|

Overall dimensions |

L (mm) |

7400 |

7600 |

8600 |

11500 |

11500 |

11500 |

12500 |

13000 |

|

w (mm) |

3500 |

5000 |

5000 |

6000 |

6000 |

6000 |

7500 |

8000 |

|

|

H (mm) |

4700 |

5400 |

5800 |

6400 |

6600 |

7000 |

7400 |

7100 |

|

|

Total weight(T) |

25 |

30 |

35 |

44 |

58 |

66 |

93 |

91 |

|

Messages

Contact

Mobile: 18940870376 (Manager Ge)

Tel:0411-87112058

Email:gmj@glospect.com.cn

Add: No. 3 Zhongxing Road, Industrial Zone, 13th Lane, Jinpu New Area, Dalian City

Glospect(Dalian) Intelligent Equipment Technology Co.,Ltd.

Glospect is a new technology innovation company established to adapt to the rapid development of the rubber and plastic industry and meet the personalized and diversified requirements of our customers. Committed to providing customers with one-stop rubber mixing solutions.

All Rights Reserved © 2023 Glospect(Dalian) Intelligent Equipment Technology Co.,Ltd. Powered by www.300.cn SEO Business License