Mixing mill

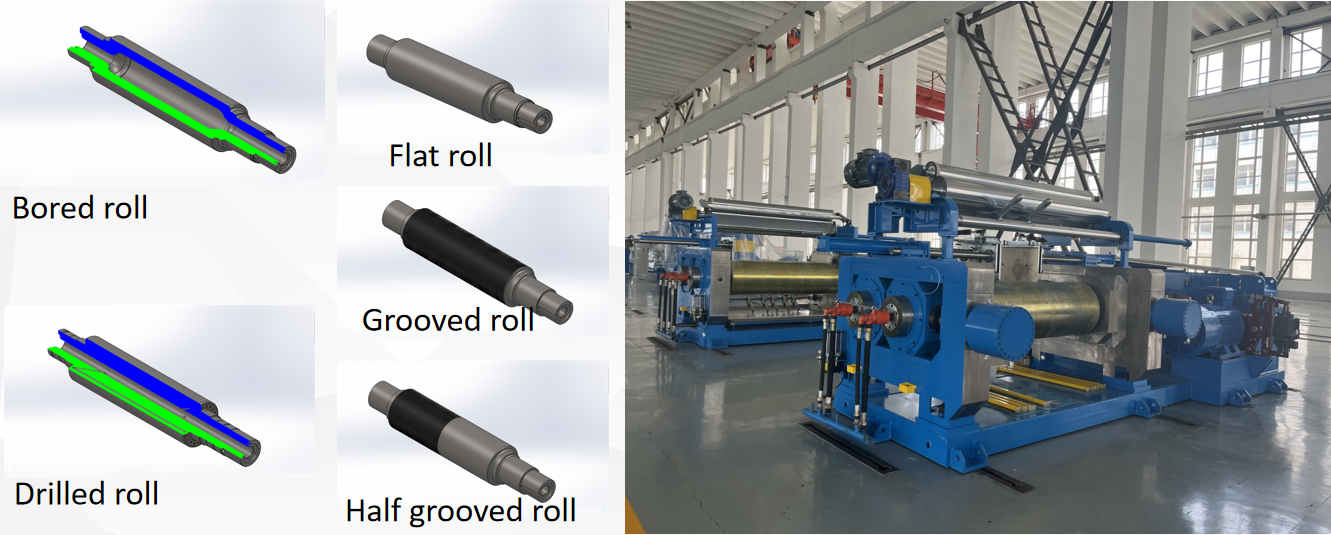

It mainly consists of roll, frame, roll nip adjustment device, and transmission device. The rubber material is pulled into the gap between two opposite rotating roll at different linear speeds under the action of friction. The rubber material is strongly sheared and squeezed through the roll gap, causing the temperature rising and increase plasticity, thereby achieving the purpose of rubber mixing and refining. The open mixing mill is a type of equipment used earlier in the rubber industry for mixing rubber. It can be used as the auxiliary machine for the internal mixer, the feeding machine for the calender, etc,

It is used for rubber mixing, plasticating, sheeting, warming, refining and rubber cracking.

Product Description:

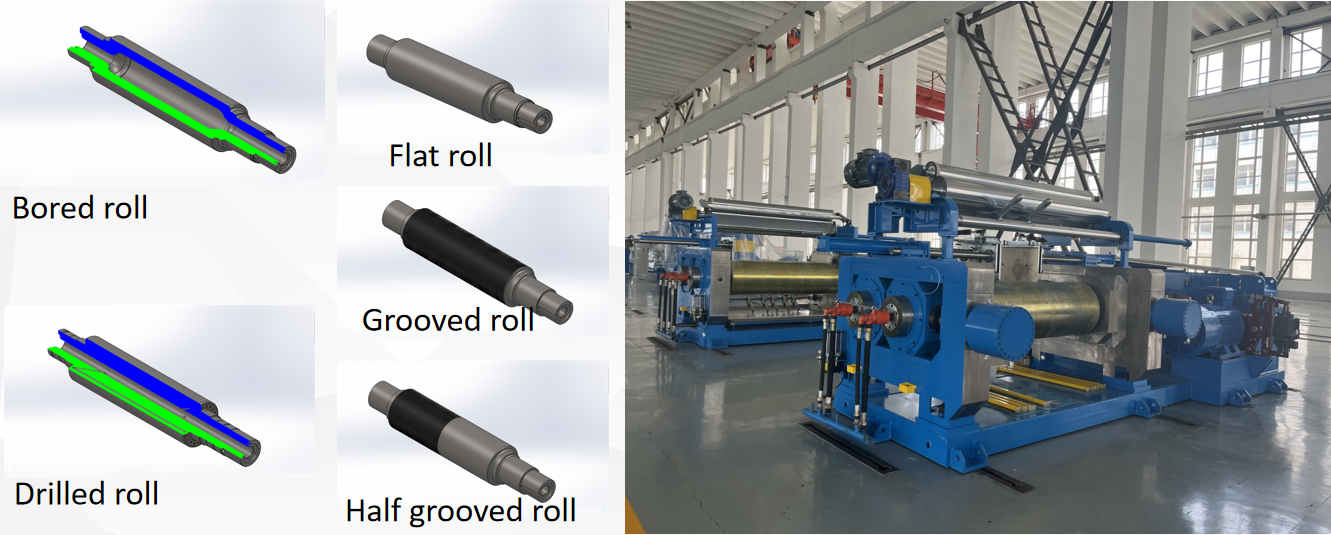

•The roll is made of chilled cast iron, the structure includes bored, drilled, fully grooved, and partial grooved type.

•There are three types for roll nip adjustment type, manual type, motorized type and hydraulic type.

•It can be equipped with the pressure sensor system to directly display the working pressure and control the feeding amount. When the pressure is overloaded, it will automatically stop immediately, then reserve and print the peak pressure data.

- Summary

- Series Products

- Technical Parameter

- 概要

-

- Commodity name: Mixing mill

Mixing Mill

Item / Model

X(S)K-160

X(S)K-250

X(S)K-305

X(S)K-360

X(S)K-400

X(S)K-450

Roll specification(mm)

Φ160x320

Φ250x620

Φ305x760

Φ360x900

Φ400x1000

Φ450x1200

Front roll speed(m/min)

10

16.96

16.3

16.22

18.78

21.1

Speed ratio

1:1.21

1:1.08

1:1.15

1:1.22

1:1.17

1:1.17

Max feeding quantity(kg)

4

15

20

30

40

55

Motor power(KW)

7.5

22

30

37

45

55

Item / Model

X(S)K-510

X(S)K-550

X(S)K-610

X(S)K-660

X(S)K-710

X(S)K-760

X(S)K-810

Roll specification(mm)

Φ510x1500

Φ550x1500

Φ610x2000

Φ660x2130

Φ710x2200

Φ760x2400

Φ810x2540

Front roll speed(m/min)

23.4

25.8

28.4

29.8

30

30

30

Speed ratio

1:1.21

1:1.17

1:1.18

1:1.09

1:1.09

1:1.09

1:1.09

Max feeding quantity(kg)

70

90

150

210

280

360

400

Motor power(KW)

90

110

160

250

160x2

355

500

-

It mainly consists of roll, frame, roll nip adjustment device, and transmission device. The rubber material is pulled into the gap between two opposite rotating roll at different linear speeds under the action of friction. The rubber material is strongly sheared and squeezed through the roll gap, causing the temperature rising and increase plasticity, thereby achieving the purpose of rubber mixing and refining. The open mixing mill is a type of equipment used earlier in the rubber industry for mixing rubber. It can be used as the auxiliary machine for the internal mixer, the feeding machine for the calender, etc,

It is used for rubber mixing, plasticating, sheeting, warming, refining and rubber cracking.

Product Description:

•The roll is made of chilled cast iron, the structure includes bored, drilled, fully grooved, and partial grooved type.

•There are three types for roll nip adjustment type, manual type, motorized type and hydraulic type.

•It can be equipped with the pressure sensor system to directly display the working pressure and control the feeding amount. When the pressure is overloaded, it will automatically stop immediately, then reserve and print the peak pressure data.

Mixing Mill

|

Item / Model |

X(S)K-160 |

X(S)K-250 |

X(S)K-305 |

X(S)K-360 |

X(S)K-400 |

X(S)K-450 |

|

Roll specification(mm)

|

Φ160x320 |

Φ250x620 |

Φ305x760 |

Φ360x900 |

Φ400x1000 |

Φ450x1200 |

|

Front roll speed(m/min)

|

10 |

16.96 |

16.3 |

16.22 |

18.78 |

21.1 |

|

Speed ratio

|

1:1.21 |

1:1.08 |

1:1.15 |

1:1.22 |

1:1.17 |

1:1.17 |

|

Max feeding quantity(kg)

|

4 |

15 |

20 |

30 |

40 |

55 |

|

Motor power(KW)

|

7.5 |

22 |

30 |

37 |

45 |

55 |

|

Item / Model |

X(S)K-510 |

X(S)K-550 |

X(S)K-610 |

X(S)K-660 |

X(S)K-710 |

X(S)K-760 |

X(S)K-810 |

|

Roll specification(mm) |

Φ510x1500 |

Φ550x1500 |

Φ610x2000 |

Φ660x2130 |

Φ710x2200 |

Φ760x2400 |

Φ810x2540 |

|

Front roll speed(m/min) |

23.4 |

25.8 |

28.4 |

29.8 |

30 |

30 |

30 |

|

Speed ratio |

1:1.21 |

1:1.17 |

1:1.18 |

1:1.09 |

1:1.09 |

1:1.09 |

1:1.09 |

|

Max feeding quantity(kg) |

70 |

90 |

150 |

210 |

280 |

360 |

400 |

|

Motor power(KW) |

90 |

110 |

160 |

250 |

160x2 |

355 |

500 |

Messages

Contact

Mobile: 18940870376 (Manager Ge)

Tel:0411-87112058

Email:gmj@glospect.com.cn

Add: No. 3 Zhongxing Road, Industrial Zone, 13th Lane, Jinpu New Area, Dalian City

Glospect(Dalian) Intelligent Equipment Technology Co.,Ltd.

Glospect is a new technology innovation company established to adapt to the rapid development of the rubber and plastic industry and meet the personalized and diversified requirements of our customers. Committed to providing customers with one-stop rubber mixing solutions.

All Rights Reserved © 2023 Glospect(Dalian) Intelligent Equipment Technology Co.,Ltd. Powered by www.300.cn SEO Business License